In the field of modern manufacturing and logistics, packaging machinery plays a vital role. With the upgrading of consumer demand and the rapid development of the e-commerce industry, packaging machinery not only improves production efficiency, but also plays an important role in reducing costs, ensuring product quality, and promoting sustainable development. This article will take you to an in-depth understanding of the main types, application scenarios, industry status and future trends of packaging machinery, and help industry practitioners, purchasers and followers to fully understand this field.

- Main types of packaging machinery

Packaging machinery can be roughly divided into the following categories according to its function and purpose:

Filling machines

Applicable to quantitative filling of liquids, pastes, powders, granules and other materials, such as beverage filling machines, sauce filling machines, powder filling machines.

Sealing machines

Used to seal packaging containers, including heat sealers, vacuum sealers, aluminum foil sealers, etc., to ensure product sealing and shelf life.

Coding and Labeling Machines

Including inkjet printers, coders, and labelers, used to mark production date, batch number, barcode and other information on packaging.

Strapping and Wrapping Machines

Mainly including balers, wrappers, and wrappers, used to fix and protect outer packaging, commonly used in logistics and warehousing.

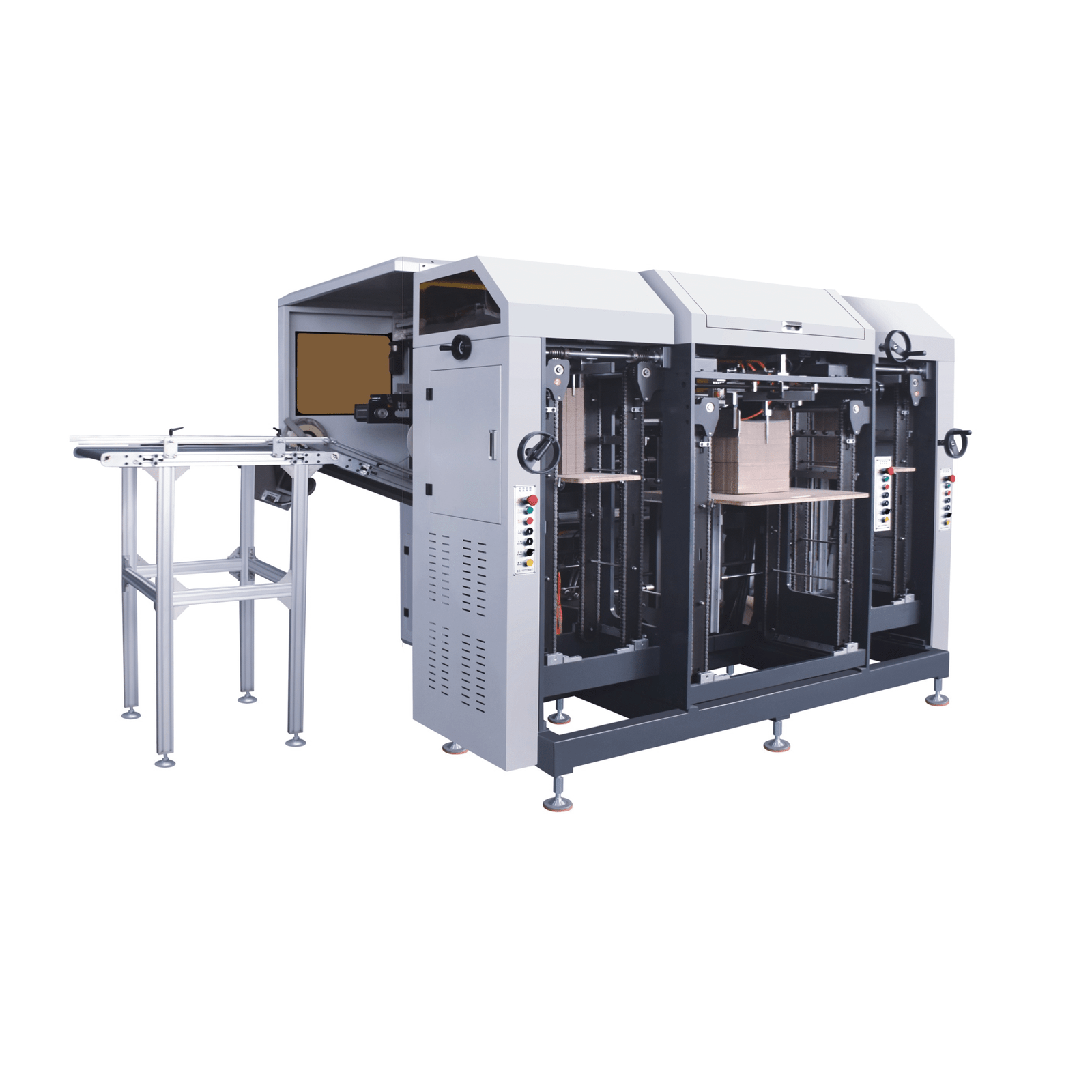

Cartoning and Case Packing Machines

Suitable for packing single products or small packages into cartons or cartons, widely used in food, medicine, daily chemicals and other industries.

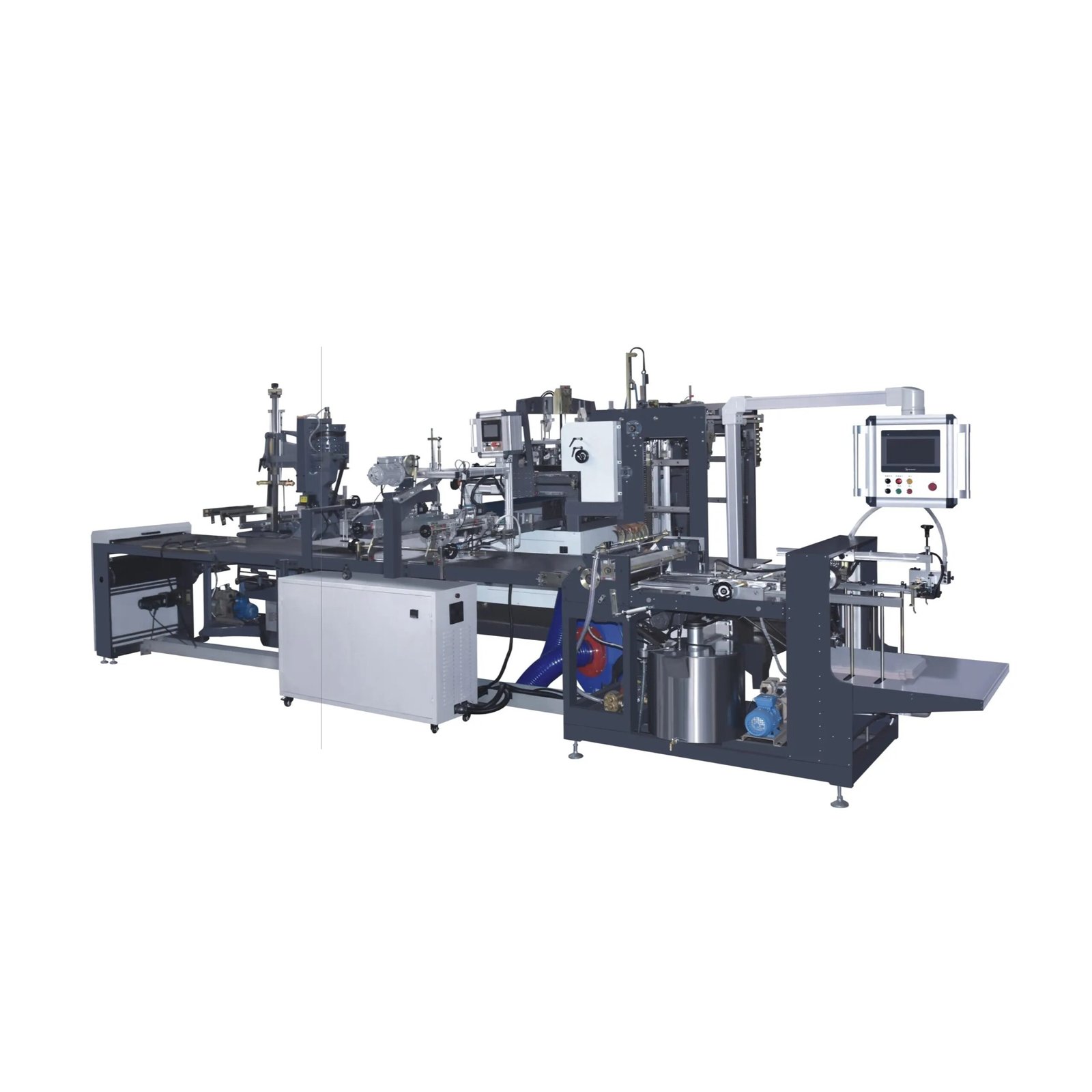

Multi-functional Packaging Machines

Integrate filling, sealing, coding, and wrapping, improve automation level, and save labor costs.

- Application fields of packaging machinery

Packaging machinery covers almost all production and circulation industries, and the main application scenarios include:

Food and beverage industry: used to package beverages, snacks, frozen foods, condiments, etc. to ensure food safety and freshness.

Pharmaceutical industry: used for bottled, aluminum-plastic plate, and blister packaging of medicines to ensure accurate dosage and reliable sealing.

Chemical and daily chemical industry: used for packaging liquid and powder products such as laundry detergent, shampoo, and paint.

Electronic products industry: used to protect electronic components and accessories to prevent damage during transportation.

Logistics and e-commerce industry: used for rapid sorting, packaging, and labeling of orders to increase delivery speed.

III. Industry status and challenges

At present, the global packaging machinery industry is showing a steady growth trend, but it also faces some challenges:

Diversified demand

Consumers’ demand for personalized, small batch, and multi-specification products has increased, and higher requirements have been placed on equipment flexibility.

Environmental pressure

Countries have increasingly stringent environmental requirements for packaging materials and processes, and companies need to introduce sustainable packaging solutions.

Cost pressure

Rising labor costs and fluctuating raw material prices have made it urgent for companies to reduce production costs through automation and intelligence.

Fast technology updates

Packaging machinery needs to continuously introduce new technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and big data analysis to improve production efficiency and product quality.

IV. Future development trends

Automation and intelligence

Intelligent functions such as automatic identification, automatic parameter adjustment, and remote monitoring will become industry standards, greatly improving production efficiency and flexible manufacturing capabilities.

Green and sustainable packaging

Equipment will use more environmentally friendly materials and energy-saving technologies to reduce carbon emissions and energy consumption.

Modular and flexible design

Modular equipment is easy to expand and upgrade to meet the needs of multi-variety and small-batch production.

Human-machine collaboration and safety improvement

Future packaging machinery will not only pursue high efficiency, but also emphasize the safety of human-machine collaboration to reduce operational risks.

Globalization and localization in parallel

While expanding globally, more and more companies focus on meeting local market needs and achieving rapid response and customization.

V. Suggestions for purchasing and using packaging machinery

For companies purchasing packaging machinery, the following suggestions are particularly important:

Clear demand: Choose appropriate equipment according to product type, output, and packaging form.

Investigate manufacturers: Choose suppliers with mature technology and perfect services to ensure equipment quality and after-sales guarantee.

Focus on energy efficiency and environmental protection: Choose energy-saving and low-consumable equipment to reduce long-term operating costs.

Train operators: ensure operational safety and improve equipment utilization.

Regular maintenance: maintain equipment, extend service life and reduce downtime.

VI. Conclusion

As an important support for modern industrial production, packaging machinery is ushering in a new stage of intelligence and environmental protection. For manufacturing companies, scientific selection, optimized management and following technological trends are the key to improving competitiveness. In the future, with the continuous improvement of market demand and technological level, the packaging machinery industry is expected to achieve more sustainable, efficient and intelligent development.