Automation is the key to transforming traditional packaging operations into highly efficient systems. Automatic tray forming machines and carton forming machines are essential tools for companies looking to improve productivity while maintaining quality.

1. Streamlined Operations

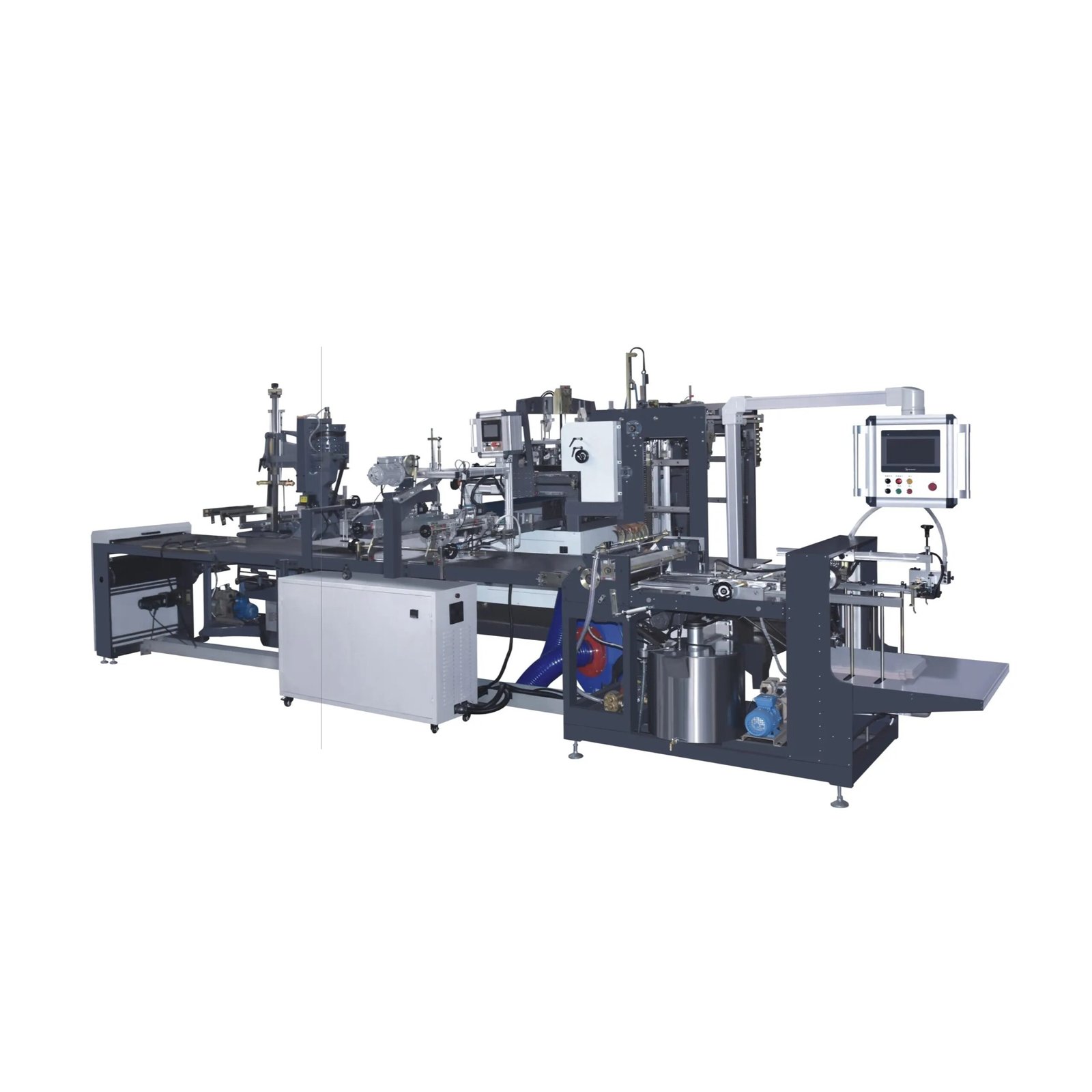

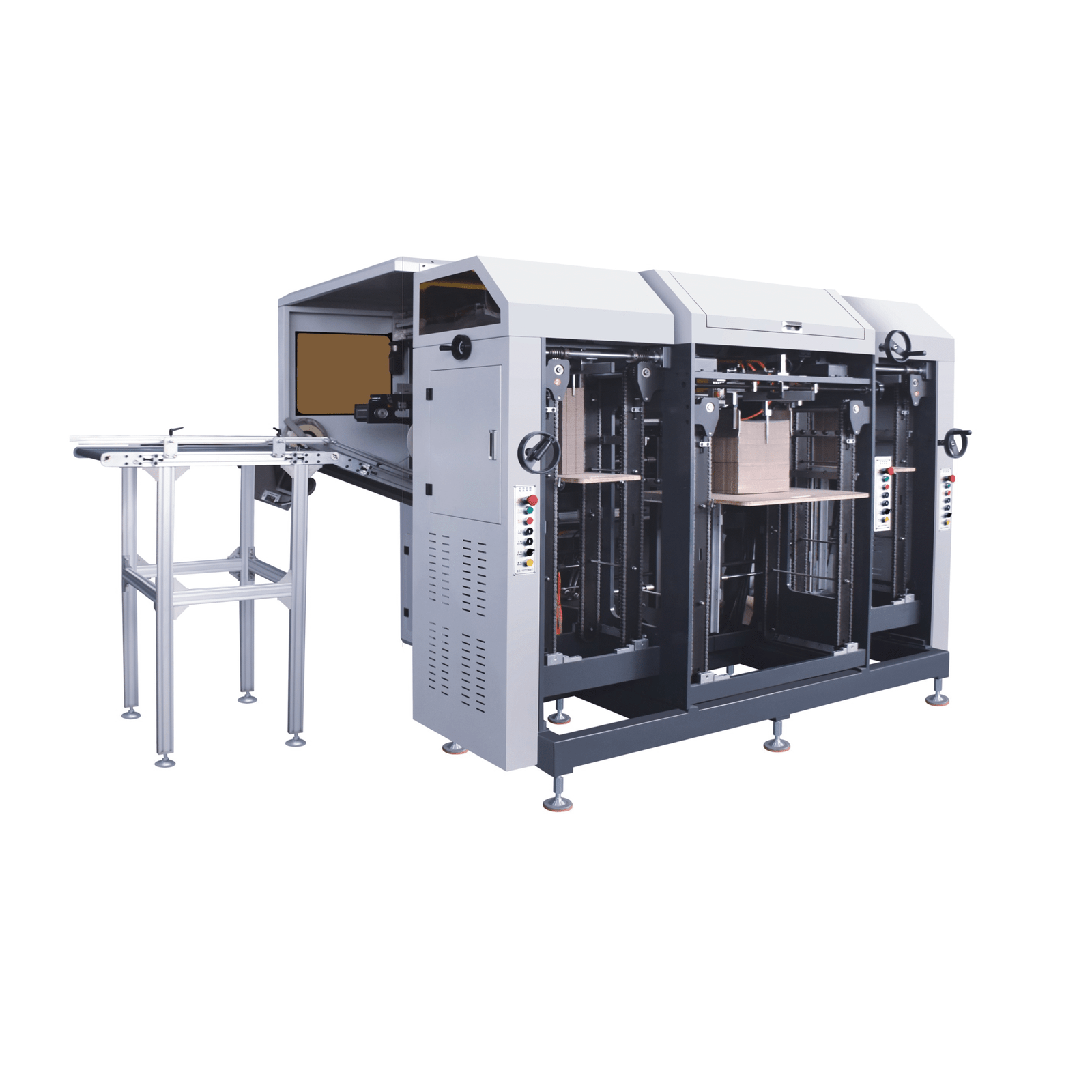

Automatic tray forming machines simplify the process of producing trays for various products. They can cut, fold, and assemble trays quickly and accurately, reducing production bottlenecks. Similarly, automatic carton forming machines streamline the creation of cartons for shipping or storage.

2. High-Speed Production

These machines are built for speed. By automating repetitive tasks, they ensure a steady flow of products while minimizing delays caused by manual labor. This results in higher throughput and faster delivery to customers.

3. Reduced Error and Waste

Manual folding and forming are prone to mistakes, which can lead to wasted materials and inconsistent product quality. Automation guarantees that each tray and carton meets precise specifications, reducing material waste and production costs.

4. Versatility for Multiple Industries

From food packaging to electronics, automatic tray and carton forming machines can be adapted to various product sizes and configurations. Their flexibility makes them suitable for a wide range of applications.

5. Integration with Other Systems

Modern machines can be integrated with other packaging equipment, such as fillers, sealers, or labeling systems, creating a seamless and fully automated production line.

By adopting automatic tray and carton forming machines, companies can significantly enhance efficiency, reduce costs, and maintain high-quality packaging standards. This technology is essential for businesses aiming to remain competitive in today’s dynamic manufacturing landscape.