Best Engineering

Company Based On

HongKong Since 2015

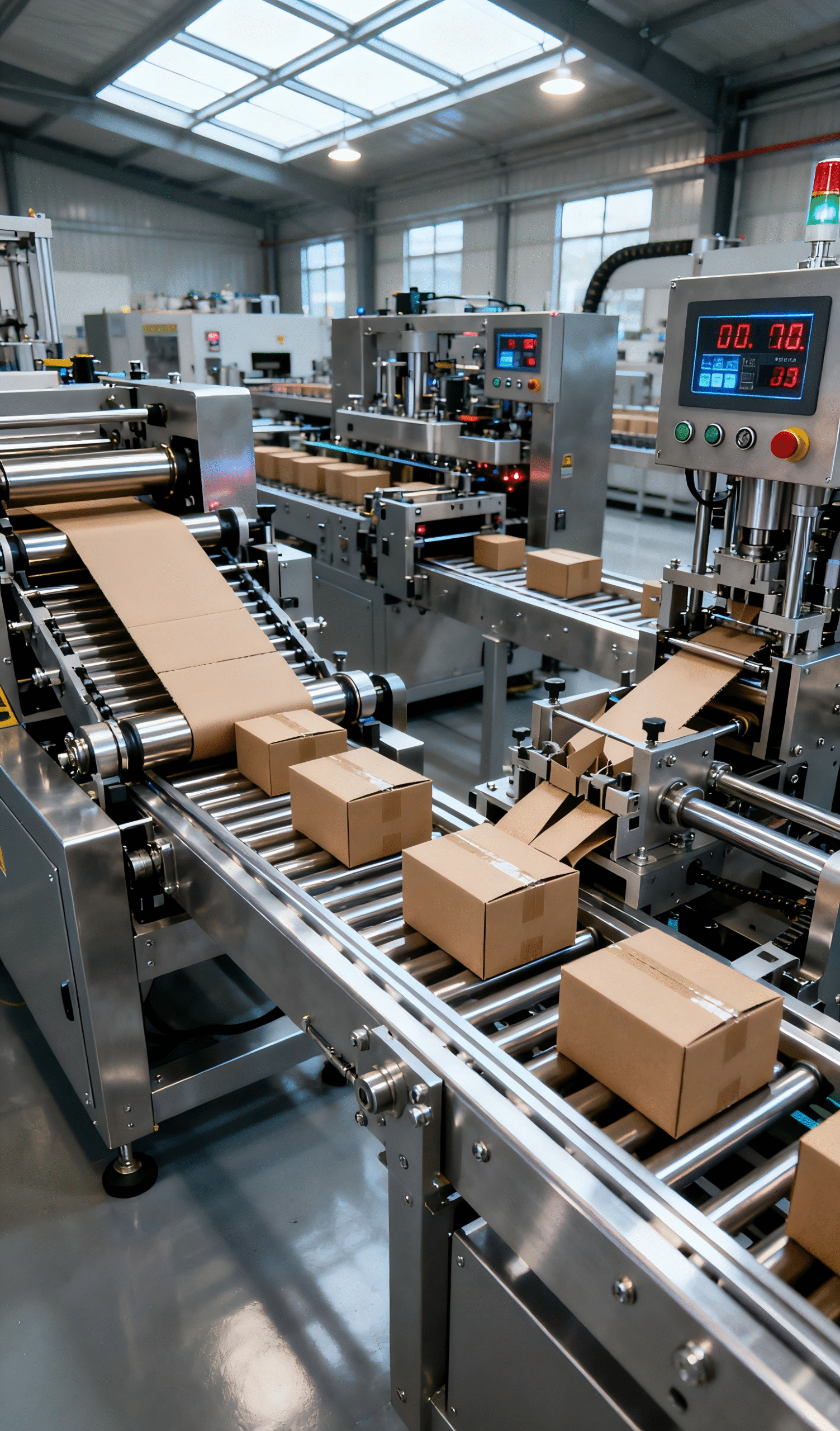

Loneshine Technology Group is a Hong Kong-registered industrial equipment supplier specializing in high-quality packaging equipment. Our production facility is located in Wenzhou, China, and is state-of-the-art. While our legal and financial operations are managed from our Hong Kong headquarters, all manufacturing, technical support, and customer service are centralized in Wenzhou. We leverage the region’s advanced industrial ecosystem to provide cost-effective, reliable, and innovative solutions to the global market.

With over 15 years of industry experience, we are dedicated to bridging the excellence of East Asian manufacturing with international trade standards, providing end-to-end services from customized production to logistics and after-sales support. We specialize in construction equipment and fully automated intelligent packaging machinery, serving a wide range of sectors, from infrastructure construction to luxury consumer goods packaging.

Years Of

Experience

Core Business Divisions

Key Products:

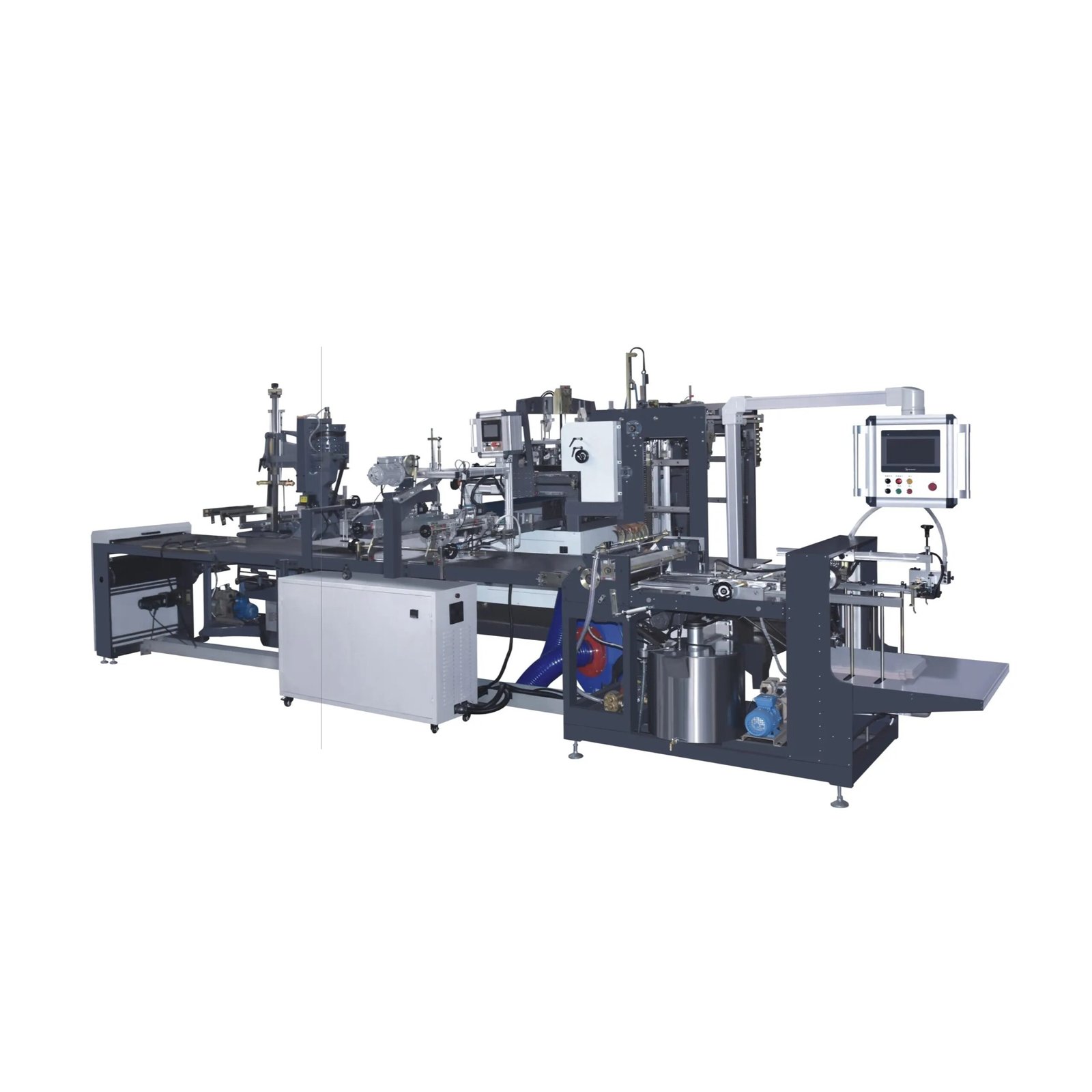

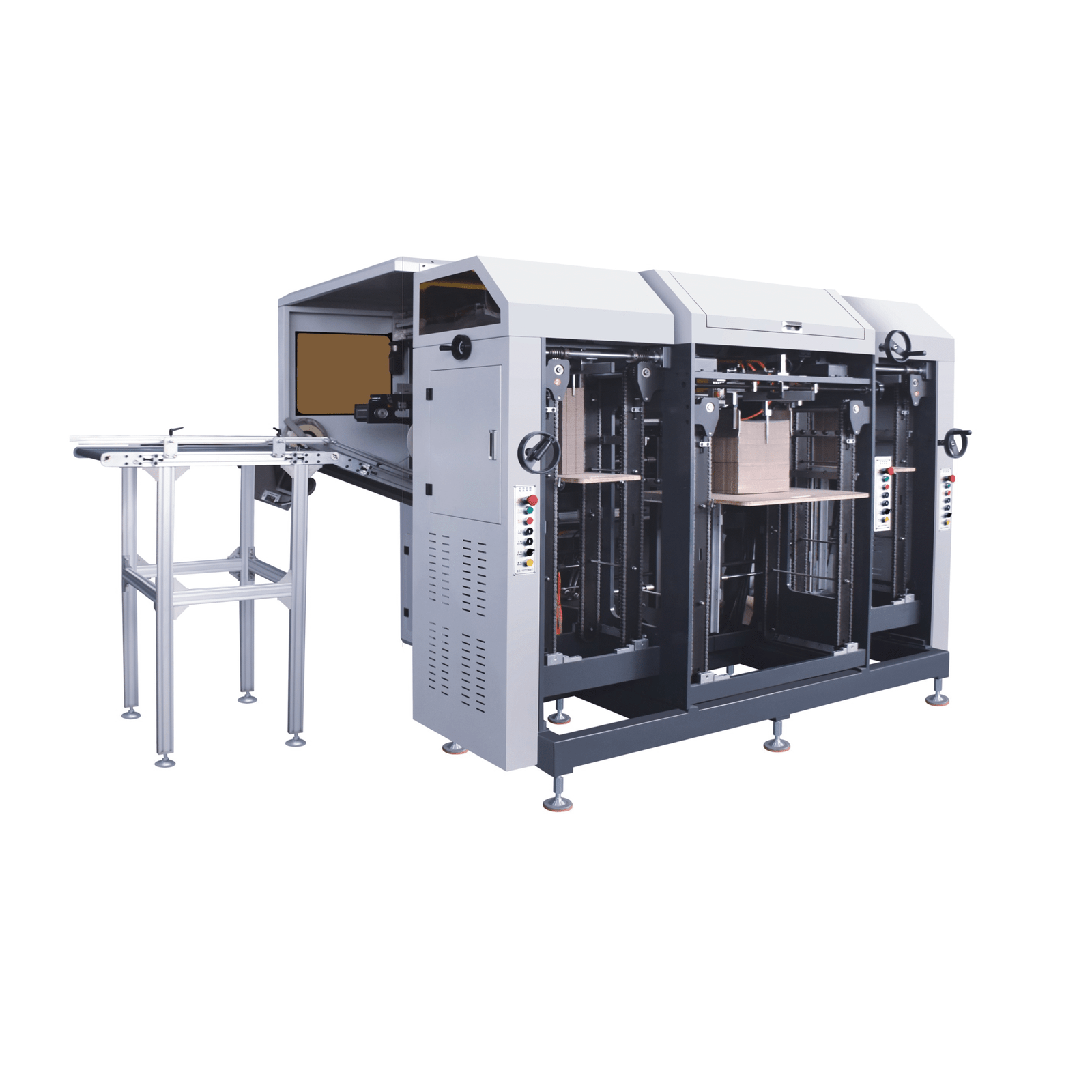

- Carton Forming Machines: Automatic box erectors, gluers, and corner pasting systems

- Precision Grooving: Laser-guided slotting equipment for luxury packaging

- Custom Solutions: Tailored machines for electronics, cosmetics, and food industries

Industry Applications:

- Luxury Packaging: High-gloss finishing for watches, jewelry, and perfumes

- E-commerce: High-speed box production for logistics

- Electronics: Anti-static packaging for smartphones and gadgets

Competitive Advantages:

- Precision Engineering: ±0.05mm tolerance for flawless packaging

- Flexible Production: Quick mold changes (under 15 minutes) for small-batch orders

- Eco-Friendly: Energy-saving designs reduce power consumption by 30%

- Zero-DefectGuarantee: AI vision inspection rejects substandard products

Success Stories:

- Vietnam: A smartphone supplier doubled daily output to 200,000 boxes.

- Germany: A sustainable packaging brand reduced material waste by 40%.

Hong Kong + Wenzhou Synergy

Hong Kong HQ: Handles international trade compliance, multi-currency transactions, and global logistics coordination.

Wenzhou Facilities: Host all R&D, production, and client visit (factory tours, training, and testing).

Transparent Client Process:

- Consultation: Dedicated English-speaking project managers.

- Customization: 3D design simulations for tailored solutions.

- Verification: Virtual or on-site factory inspections.

- Delivery: EXW/FOB/CIF options with real-time tracking.

- After-Sales: Remote diagnostics + overseas technician networks.

Quality Commitment

Construction Equipment: 100-hour pre-shipment stress tests.

Packaging Machines: 72-hour continuous run trials before delivery.

Certifications: CE, ISO, and GOST-R for key markets.

Why Partner With Us?

Manufacturer-Direct Pricing (No middlemen)

Hybrid Advantages: Hong Kong trade flexibility + Mainland China production capacity

Risk-Free Trial: Sample machines available for testing

Global Reach: 30+ countries served with localized support partners