In today’s fast-paced manufacturing environment, efficiency, precision, and reliability are crucial in the packaging industry. Smart cartoning machines have emerged as one of the most innovative solutions for businesses seeking to streamline their packaging process and reduce labor costs.

1. Enhanced Efficiency

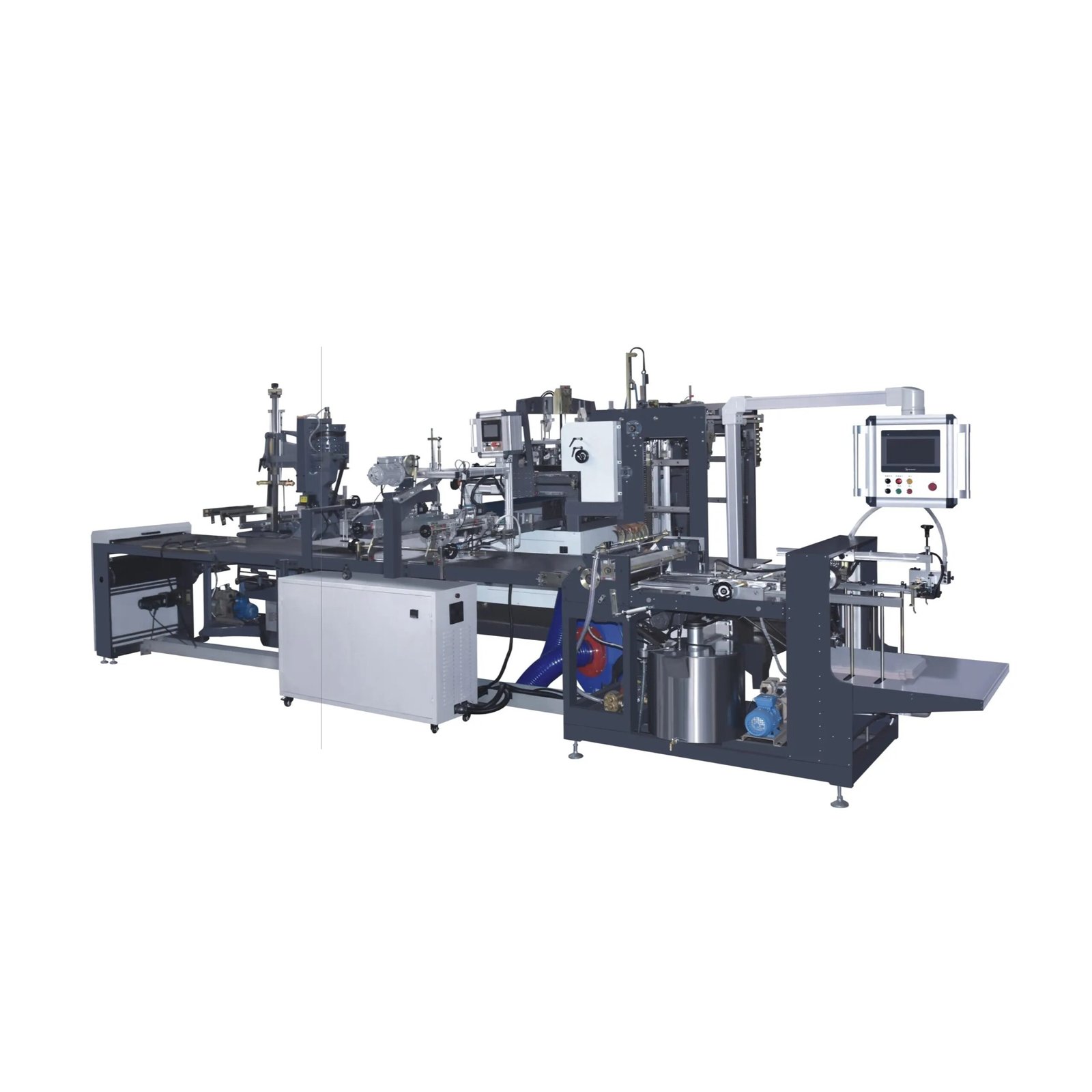

Smart cartoning machines can handle a wide variety of carton sizes and types automatically. From folding, filling, to sealing, these machines perform multiple functions without manual intervention. This not only reduces human error but also increases production speed, helping businesses meet tight deadlines.

2. Precision and Consistency

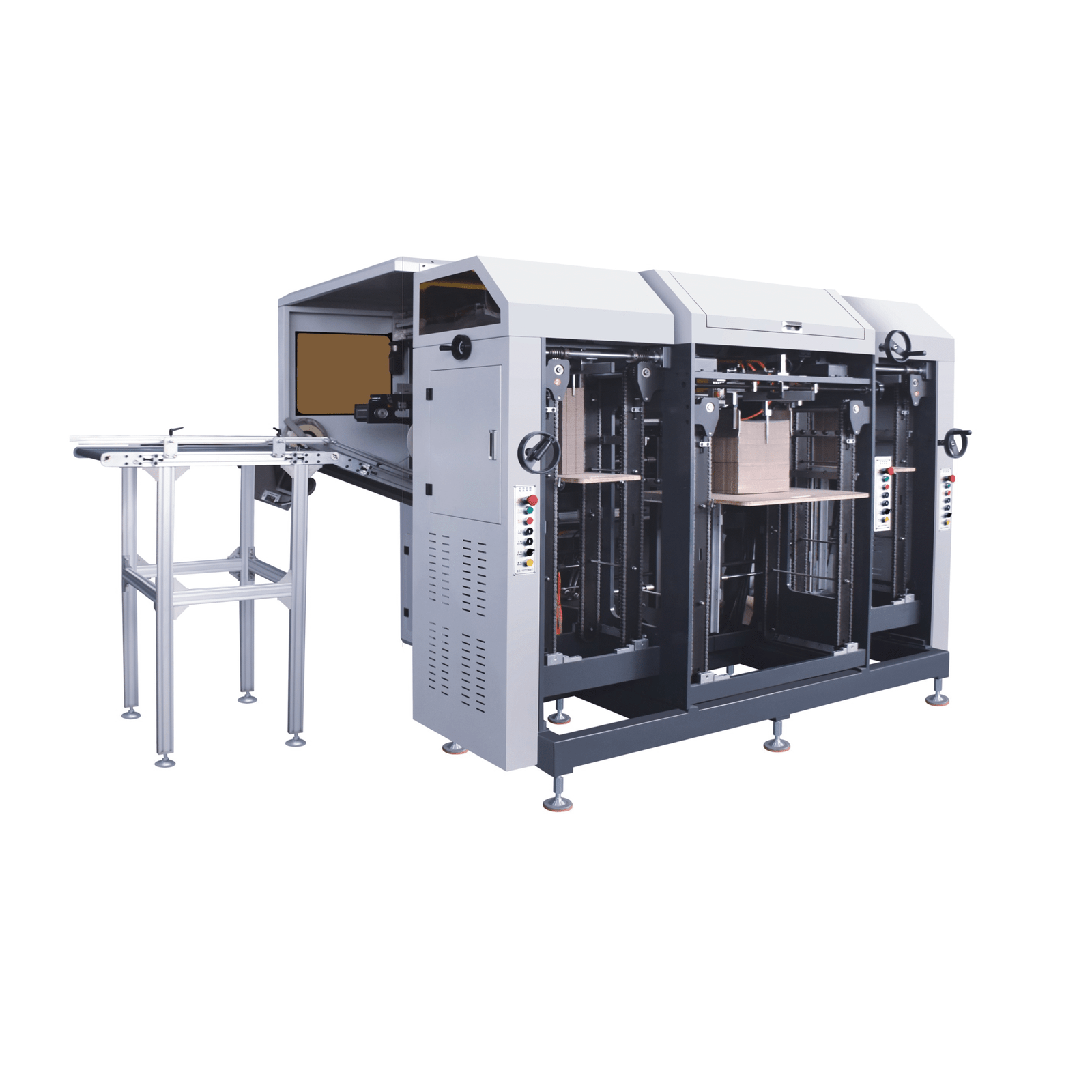

One of the most important advantages of smart cartoning machines is the consistency they offer. Every carton is folded and sealed with precision, ensuring uniformity across the production line. This is critical for companies that prioritize product presentation and quality assurance.

3. Adaptability and Flexibility

Modern smart cartoning machines are designed to adapt to various packaging requirements. They can handle different product shapes and sizes, making them ideal for diverse industries such as pharmaceuticals, cosmetics, and food processing.

4. Cost Savings

By automating the cartoning process, businesses can significantly reduce labor costs and minimize material waste. Less waste means a more sustainable production process and better profitability.

5. Future-Proof Technology

With the integration of IoT and smart sensors, these machines can provide real-time monitoring, predictive maintenance, and seamless integration with other production systems. This ensures your packaging line remains efficient and up-to-date with modern manufacturing standards.

In conclusion, investing in smart cartoning machines allows companies to optimize their production lines, maintain high product quality, and stay competitive in the packaging industry.